Process Chillers

Introducing the Canthus Process Chiller, your solution for achieving precise and efficient cooling in complex industrial processes. Engineered to deliver reliable performance and exceptional temperature control, this chiller is ideal for a variety of applications that demand high efficiency and consistent cooling.

| Model | CR1PC | CR3PC | CR5PC | CR7.5PC | CR10PC | CR12PC | CR15PC | CR20PC | CR24PC |

|---|---|---|---|---|---|---|---|---|---|

| Dimensions (LXWXH) (mm) | 508X812X920 | 660X1016X1220 | 762X1143X1524 | 508X812X1778 | 962X1220X1778 | 1062X1220X1878 | 1162X1420X1878 | 1162X1620X1878 | 1362X1620X1960 |

| Nominal Cooling Capacity | 3.5 kW/1TR | 10.5kW/3TR | 17.5 kW/5TR | 26kW/7.5TR | 35kW/10TR | 42kW/12TR | 52.5kW/10TR | 70kW/20TR | 84kW/24TR |

| Water Reservoir (ltrs.) | 40 Liters SS-304 | 100 Liters SS-304 | 150 Liters SS-304 | 200 Liters SS-304 | 250 Liters SS-304 | 300 Liters SS-304 | 350 Liters SS-304 | 500 Liters SS-304 | 500 Liters SS-304 |

| Compressor Type | Rotary 1 No. | Rotary 1 No. | Scroll 1 No. | Scroll 1 No. | Scroll 1 No. | Scroll 1 No. | Scroll 2 No. | Scroll 2 No. | Scroll 2 No. |

| Condenser | I.G Copper Tubes & Aluminum Fins | I.G Copper Tubes & Aluminum Fins | I.G Copper Tubes & Aluminum Fins | I.G Copper Tubes & Aluminum Fins | I.G Copper Tubes & Aluminum Fins | I.G Copper Tubes & Aluminum Fins | I.G Copper Tubes & Aluminum Fins | I.G Copper Tubes & Aluminum Fins | I.G Copper Tubes & Aluminum Fins |

| Evaporator | Brazed plate HX (SS 316 Plates) | Brazed plate HX (SS 316 Plates) | Brazed plate HX (SS 316 Plates) | Brazed plate HX (SS 316 Plates) | Brazed plate HX (SS 316 Plates) | Brazed plate HX (SS 316 Plates) | Brazed plate HX (SS 316 Plates) | Brazed plate HX (SS 316 Plates) | Brazed plate HX (SS 316 Plates) |

| Refrigerant | R22 / R407C | R22 / R407C | R22 / R407C | R22 / R407C | R22 / R407C | R22 / R407C | R22 / R407C | R22 / R407C | R22 / R407C |

| Water Circulation Pump | 20 LPM @ 2 kg/ cm^2 | 40 LPM @ 2 kg/ cm^2 | 70 LPM @ 2 kg/ cm^2 | 100 LPM @ 2 kg/ cm^2 | 120 LPM @ 2 kg/ cm^2 | 150 LPM @ 2 kg/ cm^2 | 180 LPM @ 2 kg/ cm^2 | 240 LPM @ 2 kg/ cm^2 | 300 LPM @ 2 kg/ cm^2 |

| Water Connections | 0.75″ BSP | 1″ BSP | 1″ BSP | 1.25″ BSP | 1.25″ BSP | 1.25″ BSP | 1.5″ BSP | 1.5″ BSP | 2″ BSP |

| Temperature Controller | Microprocessor Based Temperature Controller | ||||||||

| Temp. Stability | (+-1) degree Celsius | ||||||||

| Total Input | 1.3kW Single phase, AC, 50Hz | 3.3 kW Three phase, AC, 50Hz | 6 kW Three phase, AC, 50Hz | 9 kW Three phase, AC, 50Hz | 12 kW Three phase, AC, 50Hz | 14 kW Three phase, AC, 50Hz | 18 kW Three phase, AC, 50Hz | 24 kW Three phase, AC, 50Hz | 28 kW Three phase, AC, 50Hz |

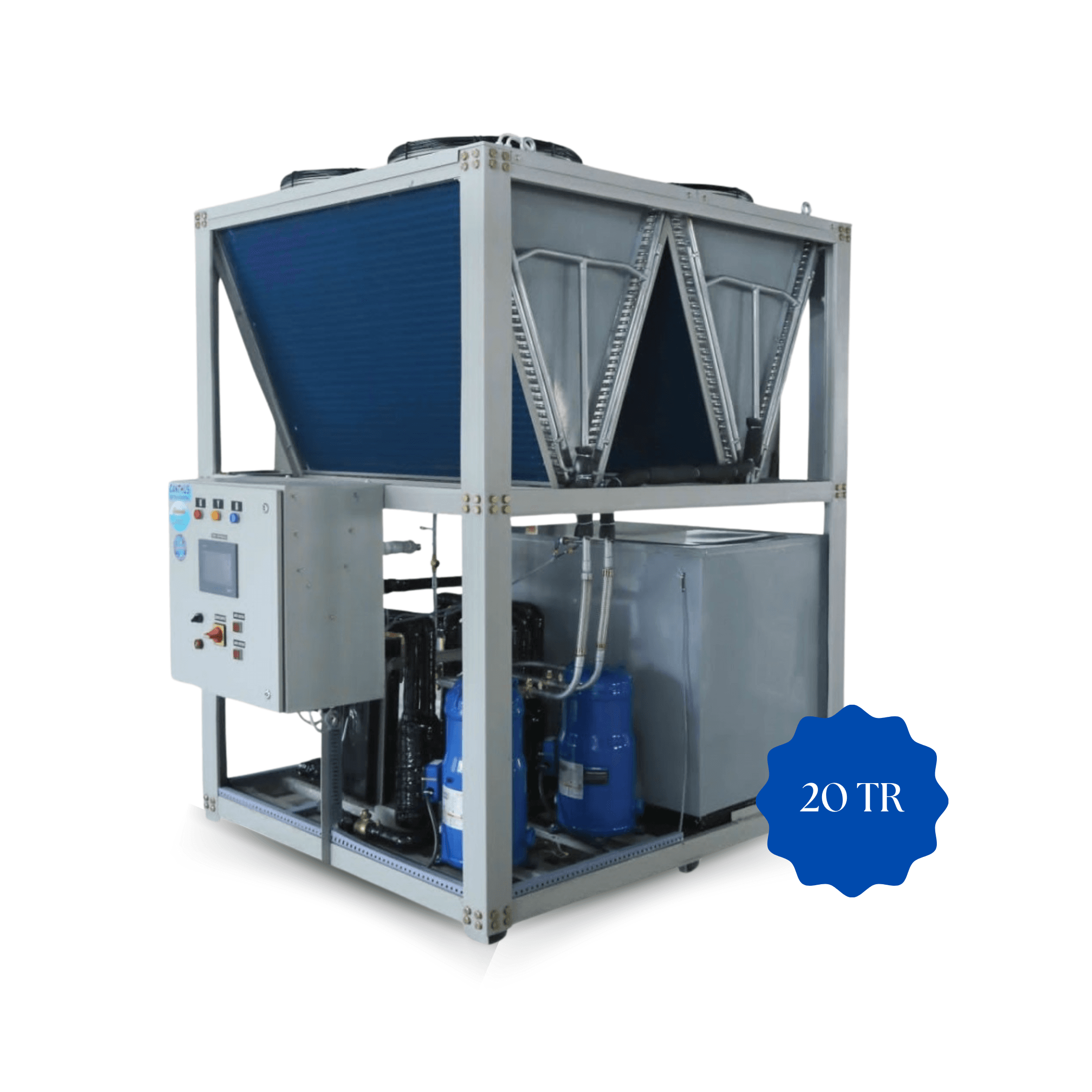

Recent Installation

- Industry: Bharat Heavy Electricals Limited

- Location: Jhansi , U.P

- Capacity: 20 TR

- Application: Designed specifically for cooling vacuum pumps and transformers

- Features: Equipped with highly efficient brazed plate evaporators and oversized corrugated fin and tube condensers, enabling it to perform efficiently even under 48°C ambient temperature

- This robust system ensures consistent performance and energy savings, even in extreme industrial environments.

Trusted by leading industries, this custom-built chiller is a perfect blend of reliability, innovation, and long-term operational efficiency.

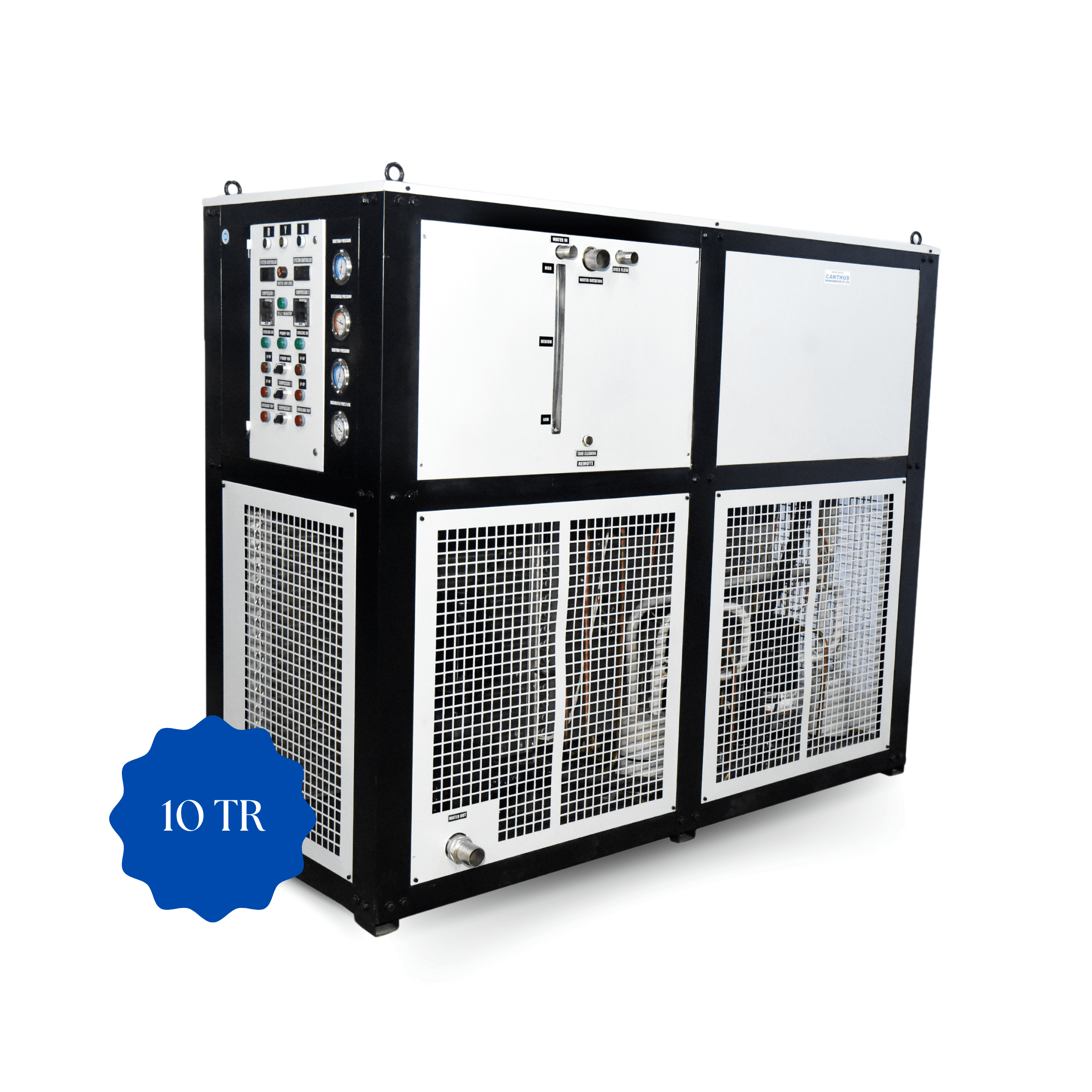

- Institute: RRCAT

- Location: Indore, M.P

- Capacity: 10 TR

- Application: Designed specifically for cooling an underwater laser cutting machine

- Features: Maintains temperature with exceptional precision—accurate to within ±0.1°C

- Engineered for high-precision industrial operations where even the slightest variation in cooling can impact performance.

This system is a reliable solution for advanced technological applications requiring consistent and ultra-precise temperature control.

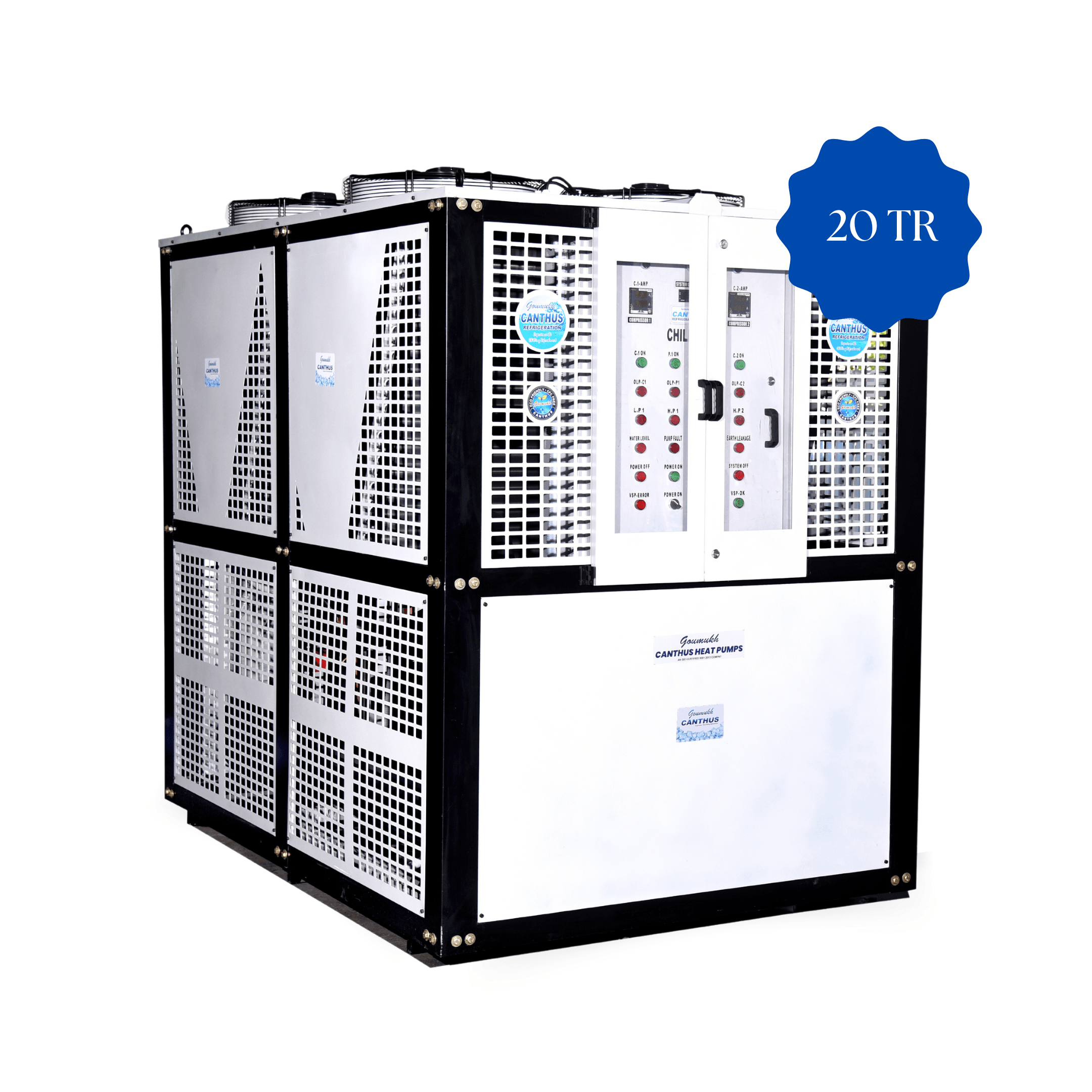

- Industry: Nuclear Fuel Complex

- Location: Hyderabad, T.N

- Capacity: 20 TR

- Application: Designed specifically for maintaining temperatures of the reactor

- Features: Dual circuit chiller with a standby pump option for uninterrupted operation

- Ensures continuous and reliable cooling for mission-critical nuclear applications where downtime is not an option.

Tailored for the nuclear sector, this high-performance chiller system guarantees efficiency, safety, and round-the-clock reliability.

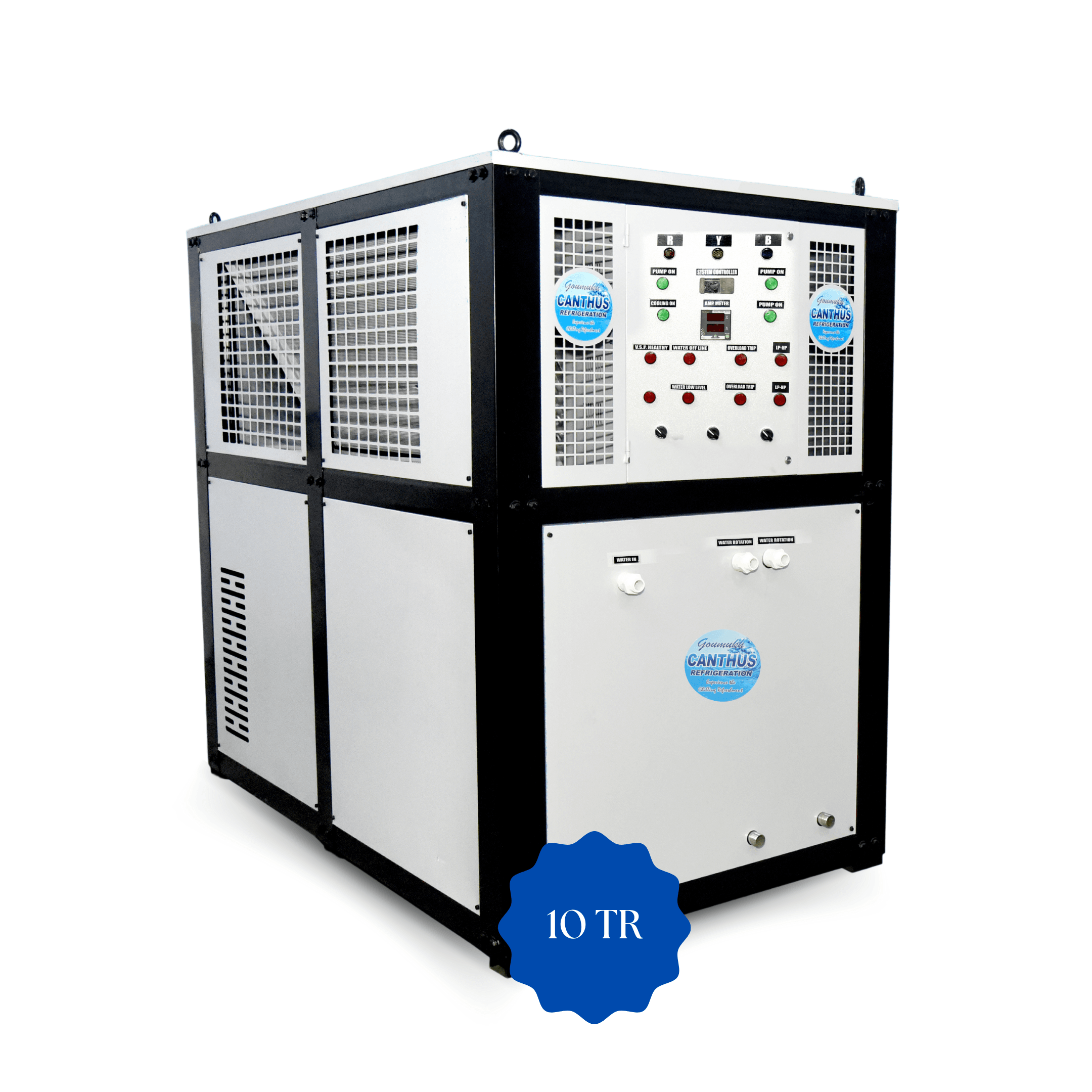

- Industry: Pragati Defence System

- Location: Bilaspur, C.G

- Capacity: 10 TR

- Application: Designed specifically for oil cooling in hydraulic press systems, ensuring optimal performance and efficiency.

- Feature: Equipped with a high-performance cooling system featuring a Shell and Tube Heat Exchanger, providing superior heat transfer capabilities and reliable cooling in demanding environments.

This advanced cooling solution is engineered to meet the high standards of the defense industry, ensuring consistent and reliable performance even in the most extreme conditions.

- Industry: Pragati Graphics

- Location: Rau, M.P

- Capacity: 10 TR

- Application: This chiller is used for cooling ink for printing machines.

- Features: All stainless steel evaporators ensure durability and long life.

This specialized chiller system is designed to maintain the optimal temperature for ink, ensuring consistent print quality and extending the life of printing equipment.

- Industry: Pepsi Co.

- Location: Jalandhar, Punjab

- Capacity: 15 TR

- Application: This chiller is designed specifically for cooling sugar syrup.

- Features: It has a wide temperature range (+25°C to –5°C).

This chiller ensures precise temperature control, maintaining the ideal environment for cooling sugar syrup and enhancing the overall production efficiency in the beverage industry.